In the world of waste management and recycling, efficiency and durability are key when it comes to compressing and securing materials for transport or storage. One essential component of this process is the strapping used to bind bales, particularly in vertical balers. Among the various types of strapping materials available, hot melt strapping has emerged as a popular choice due to its high performance and versatility.

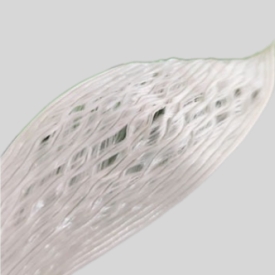

Hot melt strapping is a type of thermoplastic strapping that utilizes a heat-sensitive adhesive to secure bales of materials such as cardboard, plastic, and paper. When applied to a bale, the hot melt adhesive softens and bonds to the surface, creating a strong and durable hold once it cools and solidifies. This makes it ideal for use with vertical balers, which are commonly employed in recycling facilities, warehouses, and industries where large volumes of materials need to be compressed and securely tied together.

One of the primary benefits of hot melt strapping is its excellent adhesive properties. Unlike traditional polypropylene or polyester strapping, which rely solely on tension to secure bales, hot melt strapping forms a permanent bond that ensures the integrity of the bale during handling and transport. This reduces the likelihood of bales falling apart, which can be particularly important when dealing with heavy or bulky loads.

Another advantage of hot melt strapping is its ability to withstand various environmental conditions. Whether exposed to moisture, temperature fluctuations, or outdoor conditions, hot melt strapping maintains its performance, offering a reliable solution for recycling facilities that deal with a variety of materials in challenging environments.

Moreover, hot melt strapping is often considered an eco-friendly option. Many manufacturers are now producing hot melt straps made from recyclable materials, making it a sustainable choice for businesses aiming to reduce their environmental footprint. The use of hot melt strapping also promotes the efficiency of the recycling process, as tightly bound bales are easier to handle and transport, thus speeding up the overall workflow.

In addition to these practical benefits, hot melt strapping is easy to use. The application process is streamlined, as it typically requires only minimal heat to activate the adhesive, which can be applied quickly and efficiently using standard baler equipment. This means less downtime during operations, improving the overall productivity of the facility.

In conclusion, hot melt strapping has proven to be an indispensable tool in the recycling industry, offering a high-performance, eco-friendly, and cost-effective solution for securing bales made in vertical balers. Its strong adhesive properties, durability under various conditions, and ease of use make it a top choice for businesses looking to improve their bale handling and transportation processes.