Efficient waste management and recycling require reliable and high-performance strapping solutions. Whether you’re compacting paper, cardboard, plastic, textiles, or general waste, securing compressed bales is essential for safe handling, transportation, and storage. At BSTSTRAP, we supply bale strapping, bale banding, and bale wire—not only for our own baling machines but also for almost all types of balers and compactors in the market.

Baled waste is often subjected to intense pressure, and without the right strapping solution, bales can break apart, leading to operational inefficiencies, safety hazards, and financial losses. The choice of strapping or wire is critical in ensuring the integrity of compressed materials throughout the recycling process.

BSTSTRAP’s comprehensive range of bale strapping and banding is designed to meet the highest industry standards, ensuring that your waste management operations run smoothly and safely. Our products are strong, durable, and compatible with various baling systems, making them the ideal choice for businesses looking to optimize their baling process.

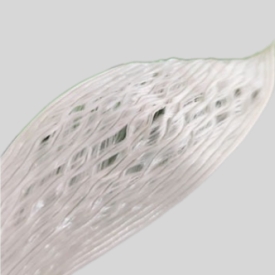

BSTSTRAP’s composite bale strapping is a high-performance alternative to steel strapping. It combines the strength of polyester fibers with the flexibility of plastic coatings, offering superior load resistance while remaining lightweight and easy to handle. Key benefits include:

High tensile strength to withstand extreme pressure in compacted bales.

Shock-absorption properties to prevent breakage during handling or transportation.

Weather and corrosion resistance for long-term durability.

Safe and easy application without sharp edges or special tools required.

For applications requiring rigid and high-strength binding, BSTSTRAP supplies polyester and polypropylene bale banding, providing a cost-effective and efficient way to secure bales in various industries. Key features include:

Consistent tension and tight hold on compressed waste materials.

Lightweight yet durable construction for easy handling and application.

Compatibility with automatic and manual balers across different industries.

For heavy-duty baling applications, bale wire remains the preferred choice for securing dense and high-pressure bales. BSTSTRAP supplies high-quality galvanized and black annealed wire, offering:

Exceptional strength to secure highly compressed waste materials.

Rust and corrosion resistance for outdoor and long-term storage.

Flexibility and ease of use for manual or automatic baling systems.

One of the key advantages of BSTSTRAP’s baling strapping solutions is their wide compatibility. Whether you are using:

Vertical balers for compacting recyclables like cardboard and plastics,

Horizontal balers for high-volume waste management,

Auto-tie balers for continuous operations, or

Compactors for reducing waste volume efficiently,

BSTSTRAP’s bale strapping, banding, and wire can be seamlessly integrated into your existing systems. Our products are designed to work with both our proprietary balers and almost all other balers and compactors in the industry, ensuring a hassle-free and reliable strapping solution for businesses worldwide.

BSTSTRAP’s bale securing solutions are trusted by businesses in diverse industries, including:

Recycling & Waste Management – Ensuring compressed recyclables remain intact.

Manufacturing & Packaging – Securing bundled materials for easy transportation.

Agriculture & Forestry – Binding compacted hay, straw, and organic waste.

Logistics & Warehousing – Improving load stability during transit.

At BSTSTRAP, we understand the importance of durability, efficiency, and reliability in bale strapping. Whether you need bale strapping, banding, or wire, our products are engineered to deliver the highest performance across various applications.

Upgrade your baling operations with BSTSTRAP’s industry-leading strapping solutions. Contact us today to find the right strapping solution for your needs!